|

Laser tools can make vias or orifices in virtually any material, from a thin plastic film to a ceramic wafer or CVD diamond coating. A tightly focused laser beam is an ideal tool, replacing hard tool bits in the manufacturing process.

Microelectronics Applications

a) Laser microvia drilling

The first photo featured below is evidence of the difference between mechanical and laser drilling. Precise positioning and excellent depth contol make lasers the tools of choice. Copper and dielectric material removal are both possible.

b) Flex circuit material removal

Flexible circuits can be laser drilled or laser skyved to produce through vias, blind vias or to remove dielectric material and expose conductive pads or fingers. Lasers are also used to excise individual circuits from panels.

c) Ceramic hole drilling and shape cutting

Alumina or any other ceramic material can be processed. Laser micromachining is the perfect way to make inside cutouts of any shape or non-linear cuts, as well as to drill precise vias in most tough and/or brittle materials.

d) Conductive film patterning

Gold, copper, ITO, and most other conductors can be patterned on a variety of substrates like glass, plastics, ceramics, etc.

e) Printed Circuit Board Repair

Silkscreen incident? Ink the wrong place? Spill something on the boards? Often times, you'll find that it's cheaper to repair the board, rather than scrap them and start over. Lasers can clean conductive pads of many types of materials, far cleaner than mechanical methods.

|

Human hair compared to a 0.013" mechanical via and a 0.005"

laser drilled via |

|

CO₂ laser drilled microvia in G-tek® (with some post-drill

processing) |

|

Material removal to expose copper fingers in a flexible circuit |

|

An example of conductive film patterning. Thin lines etched in gold plated mylar. |

Medical Applications

a) High Precision orifices in angioplasty balloons and catheters

The precision, repeatability and cleanliness of the laser drilling operation is ideal for state of the art catheter and angioplasty devices. Small holes can be placed into these devices in a variety of different configurations to allow for inflation of the balloons as well as for precise, localized delivery of small quantities of restenosis inhibiting drugs. Many shapes can be used including circles, squares and slots.

b) Drilled orifices in injection molded disposables

Laser technology offers a cost effective method for drilling in high volume mass production parts.

|

|

| An example of exposing copper pads |

For reference, this is the full device. |

Flat Panel Repair

PhotoMachining, Inc. announces the FPR2000, flat panel laser repair tool. This tool is useful in the manufacture of flat panel products including touch screens and digital x-ray detectors. The tool uses a very high precision x/y linear table with 0.1 micron encoders and feedback which is mapped to traceable standards to better than 2 micron accuracy over a 24" x 24" area.

The laser source is a New Wave green/UV laser delivered through a Mitutoyu microscope head with automated objective changing and automated z axis adjustment to compensate for part irregularities. These two wavelengths allow the removal of a variety of thin films. Other lasers are available as an option.

Other Applications

a) Marking

Lasers are successfully used to mark many materials. Ceramic or metal parts, plastic catheters, precious stones or glass windows can be perfectly marked with a properly chosen laser. The marks can be either engraved or stand out as areas of different color resulting from laser-induced photo-chemical reactions.

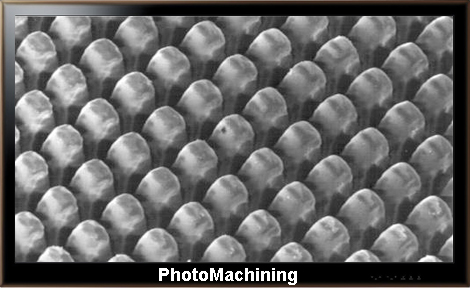

b) Inkjet hole drilling

This is another example of precision material removal with high reproducibility and in very high production volumes.

c) Other plastic and polycarbonate machining

Using different laser types, different effects and quality of cuts can be created in a variety of plastic, polyimide, and other polycarbons. View some examples of sample cuts made in mylar versus Kapton. If you have questions about a specific application, contact us and inquire about possible samples.

|